Now, the question of how golf balls are made depends on the era they were made. Nowadays, modern 3-piece and 4-piece golf balls are fundamentally different from the golf balls of the early Scottish golf era. Also, the modern golf balls must meet the specifications of several governing bodies of golf - the United States Golf Association (USGA) and the R&A of St. Andrews, Scotland. One fun fact is that R&A and USGA sanctioned differently sized balls, which means that US and European golf tournaments were played with different golf balls.

Now, venture forth in a historical, evolutional journey of how golf balls are made through different eras!

Wooden Golf Ball

Period: 1400s to 1618

Material: wood

Albeit it is impossible to determine the specific origin date of golf (and hence the golf ball), we can give credits to Scotland for a golf game and ball invention. The first real golf ball was carved out of hardwood (usually beech) with hand tools. Of course, the hardwood was shaped into round spheres we know and love today.

Now, there are some significant drawbacks to this old golf ball design. As the main material was wood, these balls were easily susceptible to moisture. The ball would quickly break in half after a number of golf club hits, combined with moisture. As the surface of the wooden golf ball was smooth, it had inconsistent air performance and short travel distance. It would take another 200 years for the golf ball design with optimized aerodynamic properties.

Well, the main benefit of the wooden golf ball is directly connected to the demographic profile of the golf players. As this kind of ball was very simple and cheap to create, people from all classes could enjoy a calm golf game, from nobility to peasants.

The Feathery

Period: 1618 to 1848

Material: feathers and leather

The introduction of the Feathery in 1618 was the first big innovation in the way how golf balls are made. This golf ball got its name because it was filled with goose or chicken feathers, which definitely isn’t the most eco and animal-friendly design nowadays.

What is the composition of the Feathery? It is composed of three separate leather parts that were stitched together to form a whole. Insides of the leather shell were filled with wet feathers and painted afterward. The feathers would dry up, expanding the ball, and giving it the rounded shape.

This ball had a much superior flight ability than the wooden golf balls, which made them relevant for more than 200 years. Still, the golf ball design wasn’t perfect at this time, as the Feathery wasn’t perfectly round, which still translated to imperfect flight ability.

Also, this ball had a long and expensive creation process. It actually took eight hours to fill one ball with feathers. Because of this tedious process, the development costs were ramped up, effectively transferring the sport to the rich class only.

The Feathery had limited durability too. You see, leather is more fragile than wood, and if it gets wet, it will come apart; exactly what would happen with this ball. After another 200 years, innovation was due to come.

The Gutty

Period: 1848 to 1898

Material: Sapodilla tree sap

This ball paved way for one of the most important golf ball design advances, which would be a mainstay to today. We are talking about the rubber material, of course. The Gutty was created by Robert Adams Patterson, who used the dried sap of the Malaysian Sapodilla tree. He discovered that the tree sap (popularly dubbed Gutta-Percha) had rubber-like qualities.

To create the Gutty, the Gutta-Percha would first be heated. Then, the heated substance would be poured into round molds. This fast development process allowed for larger production and lower production costs. The golf game would be available to the common folk again, not just reserved for the richer elite.

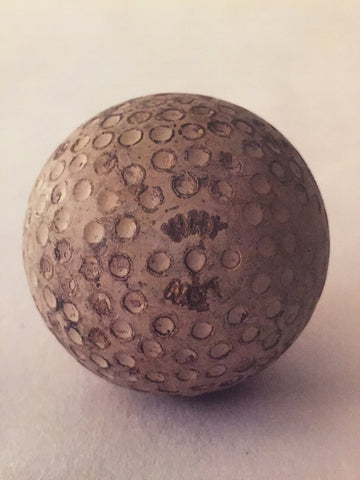

With the Gutty, people discovered the impact that indentations on the golf ball have on aerodynamic performance. Manufacturers began experimenting with hammering the ball, making imperfections in the construction that would stabilize the flight ability of the ball. This was allegedly discovered by accident!

Soon after this discovery, manufacturers would chisel and carve different textures on the surface of the ball, to find the best pattern for optimized aerodynamic performance. This design choice is the precursor of the dimples found on the modern golf balls.

The Haskell Ball

Period: 1899 to mid-1900s

Material: rubber

Just fifty years after the invention of the Gutty, another big innovation to how golf balls are made would arrive. There is an interesting story behind the development of the Haskell Ball.

The story goes that Coburn Haskell and Bertram Work wanted to play a golf game together. While Haskell was waiting for Work, he passed the time by shaping a long rubber band into a ball. He bounced this “ball” on the ground and was surprised and delighted at the same time at how high it bounced back.

After this discovery, both Haskell and Work got to the idea of putting a hardcover around the rubber, effectively creating the ball. Little did they know that their design would stay a staple, even in modern times.

Modern, Plastic Golf Ball

Period: mid-1900s to today

Material: plastic

When we observe from the design aspect, nothing much has changed from the time of the Haskell Ball. What changed are the advances in material quality. We have access to improved plastics, silicone, and synthetic rubber.

Nowadays, golf balls are widely customizable, thanks to the materials such as surlyn (an ionomer), and urethane, which are utilized to suit the needs of various golfers. Hence, the inception of multiple layers to golf balls, with different development processes. Today, we can find 2-piece, 3-piece, and 4-piece golf balls around. One company has even managed to create a 5-piece golf ball!

2-Piece Golf Ball

This type of modern golf ball features a solid rubber core, surrounded by a durable thermoplastic cover. First, the rubber block is heated and molded into a sphere - which is a core. The core is put in an injection mold, where the hot plastic is injected, which creates a hard and dimpled core coating. Afterward, the ball is painted, the logo is stamped, and a glossy finish is added.

This type of modern golf ball has longer durability and flight distance. Also, the time to develop this kind of ball is very short, as one day is required to create a ball.

3-Piece and 4-Piece Golf Balls

These types of modern golf balls are fundamentally similar, with one key difference. The 3-piece ball features a solid rubber core, a molded rubber outer core, and a final cover. On the other hand, the 4-piece ball has the same solid and molded rubber cores, as well as the final cover. The key difference is that the second coating is applied over the outer core, just before the application of the final cover.

These additions to 3-piece and 4-piece golf balls provide a smoother feel for the golfer, and a higher ball spin rate, which equals in more control. The only downside to these golf balls is their difficult and long development time. It requires over 80 different manufacturing steps, up to a month, to create these balls.

________________

Now that you know the history of how golf balls are made, feel free to check out our golf ball designer tool, free of charge!

Have any more questions about golf balls? You can reach us through email or live chat!